Baumer hhs supplies you with tailored products for the application of cold glues and liquids. Our products are used in folding carton production, corrugated board production, print finishing and many other applications. Baumer hhs is the partner of the internationally leading machine manufacturers and packaging producers.

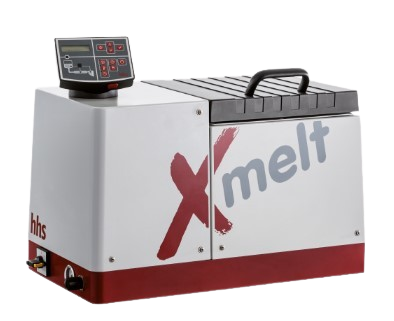

XM-100FC Designed for e-commerce.

The Xmelt melters are designed for a wide range of industrial applications. The efficient units with their high melting rate are suitable for the production of e-commerce boxes made of corrugated board.

— Two zone tank

— Up to 2 hose connections

— One or two piston pumps

— Capacitive level monitoring

— Auto ECO Mode.

The Xmelt melters are designed for a wide range of industrial applications. The efficient units with their high melting rate are suitable for the production of e-commerce boxes made of corrugated board.

— Two zone tank

— Up to 2 hose connections

— One or two piston pumps

— Capacitive level monitoring

— Auto ECO Mode.

XM25 Saves energy and protects the adhesive.

The Xmelt melters have been developed for a wide range of applications in various industries. The efficient units are characterised by low energy consumption and thus help to minimise the CO2 emissions of your production.

— Two zone tank

— Up to 8 hose connections

— Bus connection

— Capacitive level monitoring

— Auto ECO Mode.

The Xmelt melters have been developed for a wide range of applications in various industries. The efficient units are characterised by low energy consumption and thus help to minimise the CO2 emissions of your production.

— Two zone tank

— Up to 8 hose connections

— Bus connection

— Capacitive level monitoring

— Auto ECO Mode.

XM12 Saves energy and protects the adhesive.

The Xmelt melters have been developed for a wide range of applications in various industries. The efficient units are characterised by low energy consumption and thus help to minimise the CO2 emissions of your production. Two zone tank.

— Up to 8 hose connections

— Bus connection

— Capacitive level monitoring

— Auto ECO Mode.

The Xmelt melters have been developed for a wide range of applications in various industries. The efficient units are characterised by low energy consumption and thus help to minimise the CO2 emissions of your production. Two zone tank.

— Up to 8 hose connections

— Bus connection

— Capacitive level monitoring

— Auto ECO Mode.

XM8 Saves energy and protects the adhesive.

The Xmelt melters have been developed for a wide range of applications in various industries. The efficient units are characterised by low energy consumption and thus help to minimise the CO2 emissions of your production.

— Two zone tank

— Up to 8 hose connections

— Bus connection

— Capacitive level monitoring

— Auto ECO Mode.

The Xmelt melters have been developed for a wide range of applications in various industries. The efficient units are characterised by low energy consumption and thus help to minimise the CO2 emissions of your production.

— Two zone tank

— Up to 8 hose connections

— Bus connection

— Capacitive level monitoring

— Auto ECO Mode.

XM-4 Saves energy and protects the adhesive.

The Xmelt melters have been developed for a variety of applications in different industries. The efficient units feature low energy consumption, helping to minimise the CO2 emissions of your production. Two-zone tank.

— Up to 6 hose connections

— Bus connection

— Capacitive level monitoring

— Auto ECO Mode.

The Xmelt melters have been developed for a variety of applications in different industries. The efficient units feature low energy consumption, helping to minimise the CO2 emissions of your production. Two-zone tank.

— Up to 6 hose connections

— Bus connection

— Capacitive level monitoring

— Auto ECO Mode.

XBM Efficient PUR bag melter.

The Xmelt PUR bag melters are user-friendly and easy to clean. The adhesive is gently melted to prevent viscosity changes and to ensure consistent production conditions.

— Melt on Demand

— Easy cleaning

— No inert gas filling necessary

— Capacitive level measurement

— Bag diameter Ø150 mm and Ø 132 mm.

The Xmelt PUR bag melters are user-friendly and easy to clean. The adhesive is gently melted to prevent viscosity changes and to ensure consistent production conditions.

— Melt on Demand

— Easy cleaning

— No inert gas filling necessary

— Capacitive level measurement

— Bag diameter Ø150 mm and Ø 132 mm.

XMK Designed for smallest quantities.

The cartridge melters of the Xmelt series are designed for productions that require only small quantities of adhesive in daily production. By using the cartridges, production can be planned perfectly. There is no need to dispose of large quantities of expensive PUR adhesive at the end of a production run.

This is cost-efficient and protects the environment.

The cartridge melters of the Xmelt series are designed for productions that require only small quantities of adhesive in daily production. By using the cartridges, production can be planned perfectly. There is no need to dispose of large quantities of expensive PUR adhesive at the end of a production run.

This is cost-efficient and protects the environment.

XMKSafety for production and employees.

The heated hot melt hoses from Baumer hhs are available in many lengths and are perfectly adapted to your application. The insulated hoses ensure a constant temperature control for maximum production safety and protects the personnel from burns.

— Suitable for the tightest of spaces.

The heated hot melt hoses from Baumer hhs are available in many lengths and are perfectly adapted to your application. The insulated hoses ensure a constant temperature control for maximum production safety and protects the personnel from burns.

— Suitable for the tightest of spaces.

XM ALThe plus in safety.

Increase the safety in your production. The hot melt hoses of the AL series from Baumer hhs all have an integrated overheating switch. Safety that lets you sleep peacefully.

Increase the safety in your production. The hot melt hoses of the AL series from Baumer hhs all have an integrated overheating switch. Safety that lets you sleep peacefully.

Tesla Pro The hot melt head for the smallest dots at the highest machine speed.

The tesla pro electromagnetic application headvalve stands for maximum performance in packaging production. With its high availability and long service life, it helps to minimise production costs and make production more sustainable.

— Maximum availability with over 1 billion switching operations

— Short actuation times and 600 Hz application frequency

— Maximum safety due to integrated overtemperature switch

— Highest flexibility up to 5,000 mPa.s.

The tesla pro electromagnetic application headvalve stands for maximum performance in packaging production. With its high availability and long service life, it helps to minimise production costs and make production more sustainable.

— Maximum availability with over 1 billion switching operations

— Short actuation times and 600 Hz application frequency

— Maximum safety due to integrated overtemperature switch

— Highest flexibility up to 5,000 mPa.s.

Tesla EVO The innovative hot melt head controled via PLC 24V.

The tesla evo provides the packaging industry with a powerful electromagnetic application head that can be controlled directly via the machine controller. The immense advantages of electromagnetic valves can now also be used in end-of-line packaging. This reduces production costs through adhesive savings and maximum availability of the packaging machines.

— Maximum availability with over 1 billion switching operations

— Simple control via SPS 24V

— Maximum safety due to integrated overtemperature switch

— Maximum flexibility up to 5,000 mPa.s.

The tesla evo provides the packaging industry with a powerful electromagnetic application head that can be controlled directly via the machine controller. The immense advantages of electromagnetic valves can now also be used in end-of-line packaging. This reduces production costs through adhesive savings and maximum availability of the packaging machines.

— Maximum availability with over 1 billion switching operations

— Simple control via SPS 24V

— Maximum safety due to integrated overtemperature switch

— Maximum flexibility up to 5,000 mPa.s.

Tesla Go The innovative application head for use on third-party systems.

The tesla go provides the packaging industry with a powerful electromagnetic application head that can be controlled directly via the machine controller. The immense advantages of electromagnetic valves can now also be used in end-of-line packaging. This reduces production costs through adhesive savings and maximum availability of the packaging machines.

— Maximum availability with over 1 billion switching operations

— Simple control via PLC 24V

— Maximum safety due to integrated excess temperature cut-off

— Maximum flexibility up to 5,000 mPa.s

— Easy integration due to competition-compatible connections.

The tesla go provides the packaging industry with a powerful electromagnetic application head that can be controlled directly via the machine controller. The immense advantages of electromagnetic valves can now also be used in end-of-line packaging. This reduces production costs through adhesive savings and maximum availability of the packaging machines.

— Maximum availability with over 1 billion switching operations

— Simple control via PLC 24V

— Maximum safety due to integrated excess temperature cut-off

— Maximum flexibility up to 5,000 mPa.s

— Easy integration due to competition-compatible connections.

Aerto Pro Electropneumatic head for bead and dot application.

The aerto pro delivers maximum application quality, even with the most difficult adhesives. The powerful long-life module with innovative sealing technology convinces with perfect application at all speeds.

— Maximum flexibility in adhesive selection

— Long service life

— Perfect dot application

— Low maintenance costs.

The aerto pro delivers maximum application quality, even with the most difficult adhesives. The powerful long-life module with innovative sealing technology convinces with perfect application at all speeds.

— Maximum flexibility in adhesive selection

— Long service life

— Perfect dot application

— Low maintenance costs.

Aerto EVO Powerhouse for end-of-line packaging.

With the aerto evo, soiling of packaging machines due to thread pull and faulty gluing is history. The powerful head ensures clean application of dots and beads even in the most difficult installation situations. Safe and precise.

— Maximum safety with temperature cut-off

— Maximum flexibility in adhesive selection

— Simple control via SPS 24V

— Flexible for dot and line application.

With the aerto evo, soiling of packaging machines due to thread pull and faulty gluing is history. The powerful head ensures clean application of dots and beads even in the most difficult installation situations. Safe and precise.

— Maximum safety with temperature cut-off

— Maximum flexibility in adhesive selection

— Simple control via SPS 24V

— Flexible for dot and line application.

Aerto Go Powerhouse for end-of-line packaging for use with third-party systems.

With the aerto go you enjoy the same advantages as with our aerto evo, only here you have the possibility to use existing systems. Due to its compatibility, the aerto go is the perfect start into the technology of Baumer hhs.

— Maximum safety through temperature shut-off

— Highest flexibility in adhesive selection

— Simple control via PLC 24V

— Flexible for dot and line application

— Easy integration due to competition-compatible connections.

With the aerto go you enjoy the same advantages as with our aerto evo, only here you have the possibility to use existing systems. Due to its compatibility, the aerto go is the perfect start into the technology of Baumer hhs.

— Maximum safety through temperature shut-off

— Highest flexibility in adhesive selection

— Simple control via PLC 24V

— Flexible for dot and line application

— Easy integration due to competition-compatible connections.

HP500 The compact application head.

With its integrated pneumatic valve, the HP-500 impresses with its compact design. It can be integrated into the tightest installation spaces and is ideally suited for integration into robotic applications, among others.

— Small installation space

— Great flexibility in the choice of adhesive

— Wide range of applications

— Extremely quiet.

With its integrated pneumatic valve, the HP-500 impresses with its compact design. It can be integrated into the tightest installation spaces and is ideally suited for integration into robotic applications, among others.

— Small installation space

— Great flexibility in the choice of adhesive

— Wide range of applications

— Extremely quiet.

HM500 The universal head with power.

With the HM-500, Baumer hhs provides an extremely powerful and flexible application head. The HM-500 is suitable for a wide range of applications in many industries.

— Special designs available

— Maximum flexibility

— Maximum flexibility in adhesive selection

— For dot and line application.

With the HM-500, Baumer hhs provides an extremely powerful and flexible application head. The HM-500 is suitable for a wide range of applications in many industries.

— Special designs available

— Maximum flexibility

— Maximum flexibility in adhesive selection

— For dot and line application.